/remixing_materials

(23_january_2022)

This first week of Exploring Emergent Technologies discussed the topic of biomaterials

though the course Remixing Mateirals. Lara Campos, an argentinian designer with an extensive

experience in creating and using biomaterials, was in charge of the workshop and during

this first session she gave us an introduction to the topic.

Lara started the session by introducing some of the projects she has been working on

these last years. Personally, I found very interesting 'Ceggmica', a project based on

creating materials from egg shells, and 'En(des)use', a project that consisted of designing

with biomaterials, giving them a use beyond experimentation.

On the other hand, Lara also highlighted the fact that materials communicate and provoke

feelings, emotions and sensations. It is relevant the way we interact with the material

itself and thinking of the way it is related to nature and culture. She showed us the

diagram on the right that explains materials in design.

Finally, she explained to us the basics of the composition of every biomaterial: a biopolymer,

a plasticizer, the additives and the solvent. Each of these components has different alternatives

one can use, that of course will give many diverse properties to the biomaterials we are cooking.

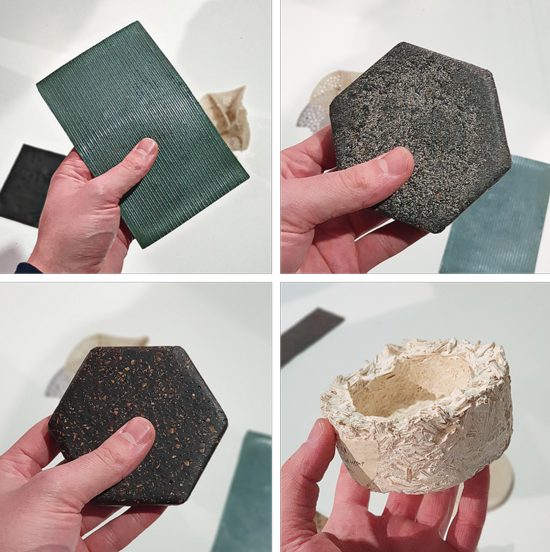

We also had the chance to touch and analyse some biomaterial samples Lara had brought and think of

some uses we could give them.

.workshop_on_biomaterials

(30_january_2022)

During this second session of Remixing Materials with Lara Campos, we had the chance to experiment

with different kinds of biomaterials using a wide diversity of food waste and colourants. Before

the workshop, we were told to collect our own food waste, dry it and grind it in order to be able

to use it for the biomaterials we were going to produce. In my case, I collected some sunflower

shells that I further ground to a small size.

The first biomaterial we created was made out of gelatine. We used the recipe to cook them and some

circular shapes with the fabric below as a mould. We poured the mix into the mould and then started

adding all the other components: eggshells, orange peels, ground coffee, fern leaves, sunflower

shells, etcetera. We also used different colours of Mica as colourants that gave the biomaterial

an amazing glossy look. Once it dried, the piece we created became stronger but also jelly and gummy.

Also, since all the water evaporated, it became much thinner and the food waste gained in importance.

Later on, we created a biomaterial using alginate as the main composite. Again, we used a cooking

pot to join all the components together and then divides the resultant dense mix in two: the first

one, we used it the same way that the gelatine one and poured it into a circular shape with fabric;

the other half was used to create threads using a syringe and a pot filled with a calcium chloride

solution.

It was surprising seeing how the liquid became solid instantly when touching the solution

and created this weird texture such as a jellyfish. When dry, the thread became much thinner and also

rigid and fragile, quite the opposite than it was before.

Finally, we used resin to create the last biomaterial. This recipe was a bit more tricky since resin

has very specific characteristics: it had to be solved in alcohol (not water), the mould needs to be

silicon or be covered with baking paper, and the cooking time is extremely important. Again, we used

our food waste and mixed it with the resin inside the cooking pot, then poured it into the mould. In

my case, I mixed the resin with the partially ground sunflower shells and ground coffee as a colourant.

Reflecting on this workshop, I think it has been a really instructive and interesting way to approach

the topic of biomaterials. As far as I am concerned, I had never worked with biomaterials before and

having the chance of getting to know this new subject has been a great experience that enables me to

further explore the opportunities of these biomaterials. I believe this is the main question now: What

can we do with that?

.further_explorations

Lara told us to keep exploring the possibilities and to try to go further, so I decided to create

an object out of biomaterial, not only a sample. The day we had the workshop I wanted to create

an ashtray out of a rigid biomaterial, probably resin. However, I didn't have enough time and material

to prepare it properly and it didn't work out well. So, I decided to develop a new ashtray from

scratch that I could reproduce as many times as I wanted.

I started thinking of an original shape for the ashtray and then 3D modelled it on SolidWorks,

taking into account that there weren't inaccessible parts nor right angles. Secondly, I sliced the

part and printed it on my 3D printer. After this, I used silicon to form the mould of the ashtray

that can be used with many different materials. Finally, I used the resin recipe doubled the

quantities and added some burnt wood and ashes to give it colour. This is the result of the

experiment:

.materials_in_context

(20_february_2022)

The following two sessions of Remixing Materials put the spotlight on Materials in Context, carried out

by Laura Freixas, MDEF alumni now working at Elisava Research. For this second part of the workshop,

we started looking for waste material opportunities around Poblenou and its surroundings. I teamed

up with Anna and Jeremy and detected some opportunities in the construction sector, the restaurant

industry, and also from the FabLab. Our experimentation interests generally focused on obsolete objects

from the trash that could be given a second life, so the opportunities selected could fit in that topic.

We finally decided to choose the material opportunity from FabLab, which was the waste from the 3D

printers: obsolete or broken 3D printed parts in PLA. PLA is considered a biomaterial since it's

made out of starch from corn in almost its totality. Currently, there are many initiatives that

transform this obsolete plastic into some other object because of its properties after melting it

again. The most famous one is Precious Plastic, where they created some DIY machines to process the

PLA parts: shredder, press, plastic injector, etc.

After this, we made a SWOT analysis for the material and also thought of the life cycle of it and

how to give it a second life. Then, we started the experimentation. For us, making all the processes

of transforming PLA parts into sheets was an unknown thing even though this is a commonly used

technique. However, since we hadn't explored this field before, it was quite fascinating to see the

results of shredding and then creating colourful sheets with an oven. The trickiest part without any

doubt was to define the settings for the oven in relation to the quantity of plastic, temperature

and time. We finally got to a pretty precise configuration that gave us strong and flat sheets:

- Silicon mould 20x25cm

- 220g of shredded plastic

- Oven at 200ºC up and down

- 10 to 15 minutes (always checking it)

The final step was to use those sheets we had in order to create new objects and products. For that,

we used the laser cutter of Ateneu de Fabricació del Parc Tecnològic to cut some designs we had

created. We also learnt how to laser cut a material that constantly melts: cutting fast and

decreasing the power and repeating twice or thrice. This is the final video from all the processes

we followed:

On the second day, every group exposed their materials and their explorations and was a good chance to get to know other possibilities of biomaterials created from waste from the neighbourhood. One of the projects I liked the most was Emilio's and Andrea's (and I don't remember if somebody else) where they used flowers from the cemetery to create a rigid material mixed with pine resin. I found it really poetic and at the same time an interesting field to explore since this is a constant waste in every cemetery and some work could be done.

To sum up this second part of Remixing Materials with Laura Freixas, this is the final submission we had to upload, where one can see all the different steps of the process we followed to get to the final result of our biomaterial. From the exploration to the reflections: